From custom stainless steel fasteners to PEEK bushings and Torlon® fittings, Defiant Manufacturing produces complex CNC-turned and Swiss-machined components built to your exact specifications. Serving industries from fasteners to aerospace, we machine complex parts from a wide range of materials with uncompromising quality.

Powered by Mazak CNC turning centers, multi-axis Integrex machines, and Swiss equipment capable of diameters down to .050”, we deliver complex geometry in single-setup, lights-out production. From prototypes to high-volume runs, Defiant offers cost-effective Midwest shop rates, tight tolerances to ±.0005, and the expertise to support projects from one piece to one million.

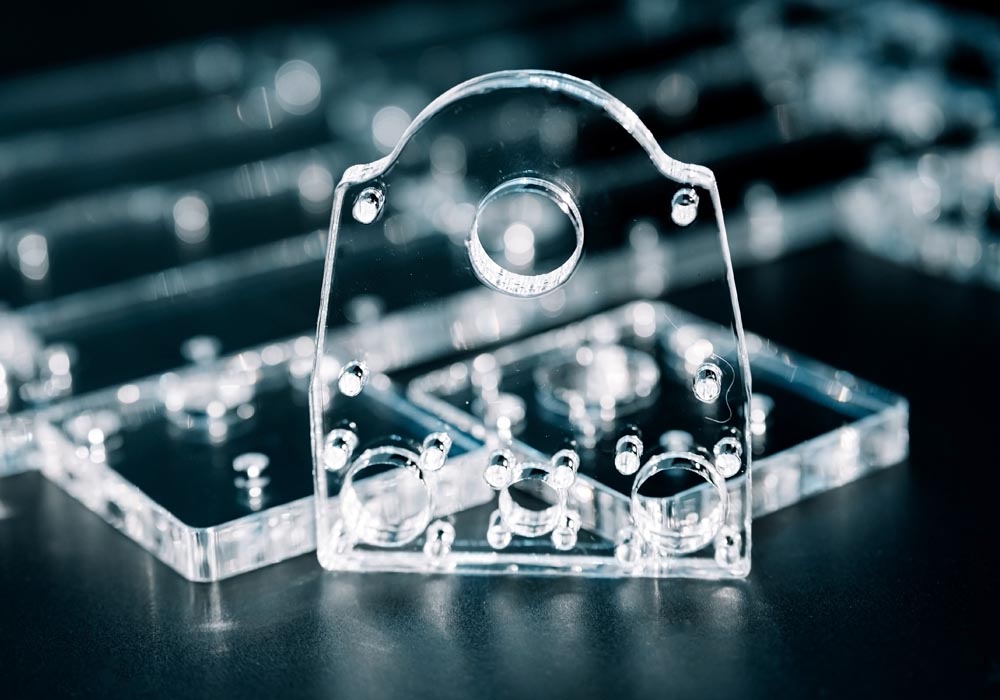

Defiant has supplied plastic CNC turned parts to a variety of OEM clients. Some components requiring tolerances as tight as +/-.0005. We are very familiar with a vast majority of thermoplastics and thermosets and their attributes. Call us today for guidance on your next design!

Below is a list of some of the materials we have worked with.

With multi axis CNC turning capabilities as we well as secondary equipment access, Defiant can provide complex components out of a variety of different alloys. If your part needs further surface finishing requirements, we can provide: passivation and cleaning, electroless nickel plating, anodizing and powder coating. Below are the alloys we can assist with:

Materials: Aluminum, Steel, Stainless Steel, Copper, Brass, Bronze.

Products Produced in both Plastic & Metal include: